Remember Solyndra? When the solar panel company went under in 2011, defaulting on a $535 million loan guarantee from the Department of Energy, it became the name Republicans would invoke whenever they wanted to attack government support for renewable energy. Well, now solar is booming, and one of the biggest companies around is moving into Solyndra’s old digs.

SolarCity has leased the 200,000-square-foot Solyndra facility and is turning it into the R&D headquarters for its new manufacturing arm, according to the Silicon Valley Business Journal. It’s just the latest move in SolarCity’s foray into panel manufacturing, which began in earnest last year with the purchase of Silevo and continued with the construction of a new factory in Buffalo, New York, which the company says will produce a gigawatt’s worth of panels a year. Because Elon Musk chairs SolarCity (his cousins Lyndon and Peter Rive are CEO and CTO, respectively), the project is sometimes called Musk’s other gigafactory — the first being Tesla’s giant battery factory under construction in Nevada.

“THIS IS COMPLETELY NEW FOR THEM.”

“This is completely new for them,” says Shyam Mehta, an analyst for GTM Research, who characterizes the move into manufacturing as “a bold decision.” But is it too bold? “It’s very tough to say right now whether it’s a stroke of genius or unnecessary,” Mehta says.

SolarCity was founded in 2006 and has been growing fast, expanding to control 39 percent of the residential solar market. (It announces its latest quarterly earnings later today.) But SolarCity doesn’t make solar panels. Instead, it installs them on people’s roofs for free, then leases the panels for less than they’d pay for energy from the grid, selling any excess back to utilities. It’s proven to be a successful model, partly because SolarCity was able to ride the plummeting cost of panels, driven by large scale production in China, that caused problems for so many American companies trying to produce their own.

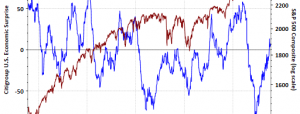

Here’s a chart of falling solar costs by AllianceBernstein’s Michael Parker and Flora Chang, who call it the terrordome, I guess because it sounds cool, and because the rapid drop in solar prices looks like falling off a cliff. (It’s utility-scale solar in developing markets, but the trend is true globally.)

SolarCity has given several reasons for its move into manufacturing. When the company purchased Silevo and announced the New York factory, Musk said it was because he sees a panel shortage coming and wants to guarantee supply. An American factory would also hedge against increased tariffs on Chinese imports, something that’s been threatened in the past.

SolarCity also hopes that Silevo can produce a more efficient panel, which is of particular importance for residential installations, where roof space is limited. When Musk announced the purchase of Silevo, he said the high-efficiency panels will make solar “way cheaper” than power from fossil fuels.

MUSK SAYS HIGH-EFFICIENCY PANELS WILL MAKE SOLAR “WAY CHEAPER” THAN FOSSIL FUELS

SolarCity’s strength as a panel installer also gives SolarCity and advantage as it moves into manufacturing, Mehta says. They’ll have a ready market for any panels they make. Vertical integration is clearly something that Musk is aiming for: he says Tesla will soon be making batteries for the home and that these batteries will come with SolarCity units. It’s a step toward a distributed power grid in which Tesla and SolarCity control power generation, storage, and the cars that use that energy. Panel manufacturing would be a major component in that chain.

Aside from competition from existing panel manufacturers, SolarCity also faces the risk of diminishing federal subsidies. The federal Investment Tax Credit is worth up to 30 percent of a project’s cost, and it’s scheduled to drop to 10 percent by the end of 2016. That drop will affect large utility-scale projects more than residential ones, which SolarCity deals with, and given the decline in panel prices, solar is rapidly becoming competitive on its own. “Things have changed fundamentally in the last three or four years,” Mehta says. “The economics of solar are so good that people are putting it up in countries without any subsidies.”

Read more: Solyndra’s old facility is getting a new tenant: Elon Musk’s SolarCity